The “Tariff Effect”: How Manufacturers Can Avoid USMCA Compliance and Triangulation Risks

Executive Context: Why This Matters Now

Nearshoring has transformed Mexico into the most strategic manufacturing platform for the U.S. market. But as production shifts accelerate, trade enforcement is tightening.

For executives, the critical question is no longer whether Mexico is the right location—but:

How can manufacturers expand in Mexico without triggering USMCA violations or triangulation risk?

The answer lies in understanding the “Tariff Effect”: the growing gap between compliant nearshoring strategies and risky pass-through operations.

The USMCA Reality: “Made in Mexico” Is Not Enough

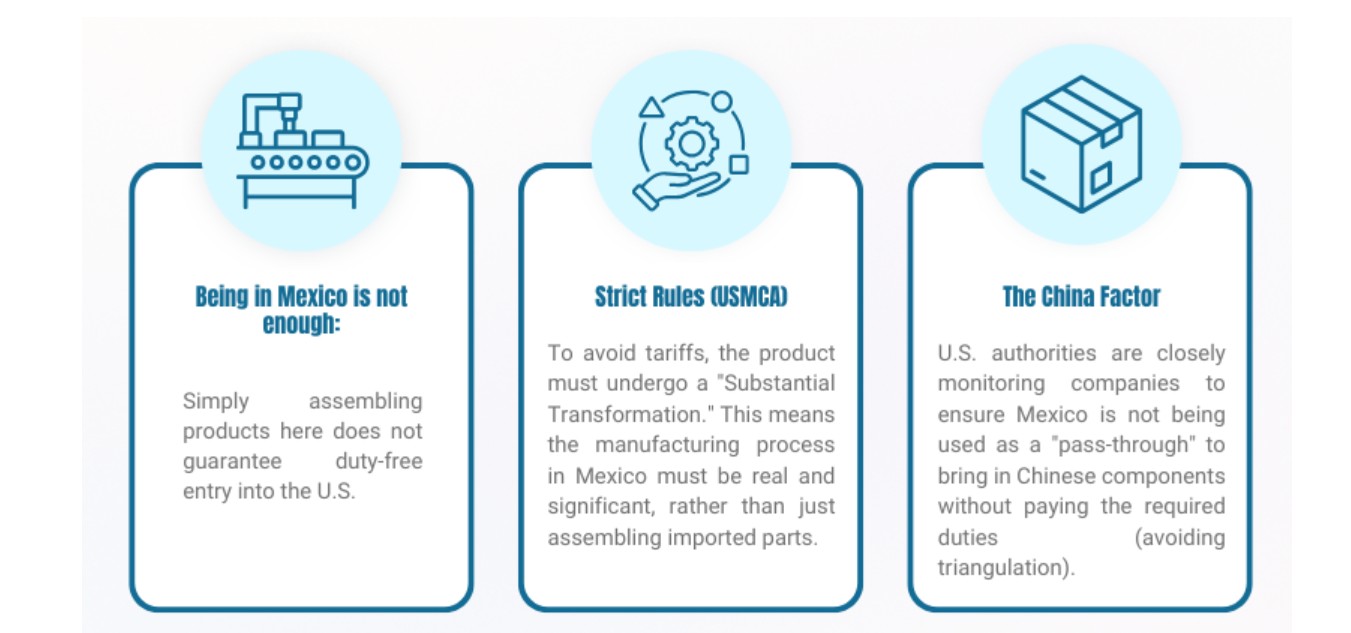

A common misconception among global manufacturers is that relocating production to Mexico automatically grants duty-free access to the U.S.

Under the USMCA, this is false.

To qualify for preferential treatment, products must meet strict rules of origin, proving that Mexico is not merely a transit point—but a genuine production location.

Authorities now actively investigate operations that appear to:

- Import mostly non-regional components

- Perform minimal assembly

- Re-export finished goods under USMCA preferences

- These cases are increasingly classified as triangulation.

Why Enforcement Is Increasing

The escalation of trade tensions—especially U.S. tariffs on Chinese-origin goods—has intensified scrutiny by U.S. authorities.

As companies attempt to mitigate tariff exposure by moving production to Mexico, enforcement agencies focus on whether:

- Real transformation occurs in Mexico

- Value creation genuinely shifts into North America

- Supply chains comply with USMCA intent

- Operations that resemble “assembly-only” models face elevated audit risk.

Substantial Transformation: The Core Compliance Test

Two concepts determine whether a product qualifies under the USMCA:

1. Tariff Shift

Imported inputs must change their HS tariff classification as a result of manufacturing in Mexico.

Example:Raw materials imported → processed into a finished product with a different HS code.

2. Regional Value Content (RVC)

Certain industries must also meet a minimum share of North American value.

This is calculated using:

- Transaction Value Method

- Net Cost Method

Failure on either test means the product is treated as non-regional—making it subject to tariffs.

The Hidden Risks of Non-Compliance

The financial and operational consequences of USMCA violations are severe:

- Retroactive tariff assessments covering years of shipments

- Detention of goods at the U.S. border

- Persistent inspections on future exports

- Loss of credibility with customers and authorities

For high-volume manufacturers, this can turn nearshoring into a material financial liability.

A Practical Framework to Reduce Tariff Risk

Manufacturers that expand successfully in Mexico follow three core principles:

1. SKU-Level Compliance

- USMCA compliance cannot be generalized.

- Each product must be analyzed individually

- Bills of materials must be traceable

- Cost structures must support RVC thresholds

2. Supply Chain Localization

Reducing reliance on non-regional suppliers strengthens compliance while improving resilience.

Benefits include:

- Shorter lead times

- Lower geopolitical exposure

- Improved ESG alignment

3. Audit-Ready Documentation

Trade compliance is only as strong as its records.

Manufacturers must maintain:

- Certificates of origin

- Production evidence

- Cost and value calculations

- Clear traceability across suppliers

Why Mexico Remains the Solution

Stricter enforcement does not weaken Mexico’s role—it reinforces it.

The USMCA is designed to:

- Protect North American manufacturing

- Reward genuine transformation

- Discourage low-value pass-through models

Mexico offers:

- Skilled labor capable of complex manufacturing

- Mature industrial ecosystems

- Integrated logistics and customs infrastructure

- A stable trade framework for long-term planning

Done correctly, nearshoring to Mexico reduces risk rather than creating it.

Conclusion: Compliance Is Now a Strategic Advantage

The “Tariff Effect” is not a temporary trade issue—it is a structural shift in how nearshoring is evaluated.

For manufacturers, the message is clear:

- Mexico is not a loophole

- Minimal transformation is no longer viable

- Compliance strategy must be built into expansion decisions

Companies that invest in genuine production, localized supply chains, and compliance discipline will secure long-term access to the North American market—without tariff exposure.

FAQ

What is triangulation under the USMCA?Routing goods through Mexico with minimal transformation to avoid tariffs.

Does nearshoring to Mexico still make sense?Yes—when production involves real transformation and USMCA compliance.

What triggers USMCA audits?High non-regional content, minimal processing, or inconsistent documentation.

Is compliance a legal or operational issue?Both. It affects trade, cost structure, timing, and long-term market access.